Electroless Nickel

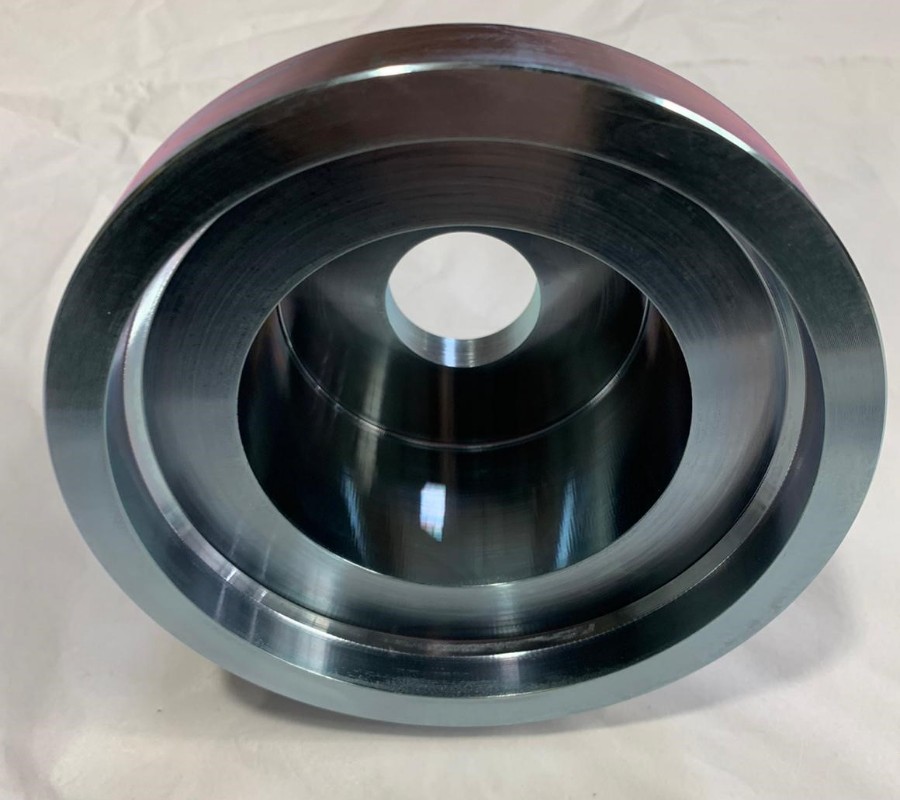

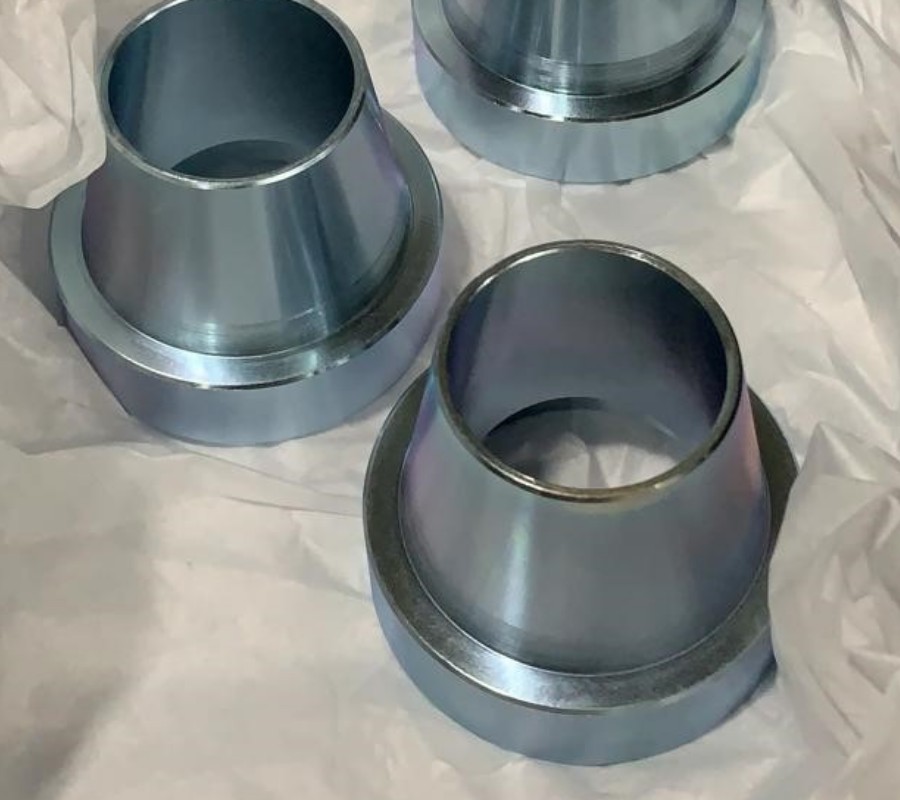

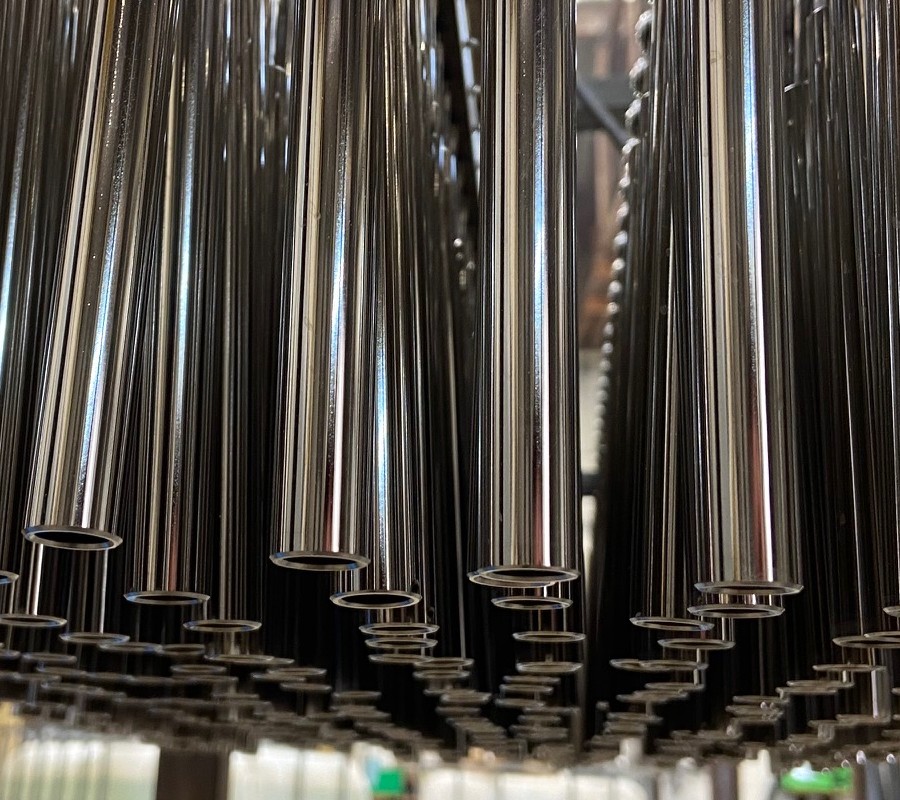

Electroless nickel plating is an autocatalytic depositing process of a nickel alloy. Other than electroplating, electroless nickel (EN) does not require rectifiers, electrical current or anodes. Plating occurs thanks to chemical reactions. Since all surfaces submerged in the electroless nickel solution are plated at the same plating rate, the deposit thickness is very constant across the part. This unique property of EN makes it possible to coat internal and external surfaces of parts uniformly.

Electroless nickel plating deposits a dense alloy of nickel and phosphorus. The deposition process is autocatalytic, i.e., once a primary layer of nickel has formed on the substrate, that layer and each subsequent layer becomes the catalyst that causes the reaction to continue. Electroless nickel deposits are functional coatings and are rarely used for decorative purposes only. The main purpose of electroless nickel generally falls within the following categories:

Benefits of electroless nickel plating

- Corrosion resistance

- Wear resistance

- Hardness

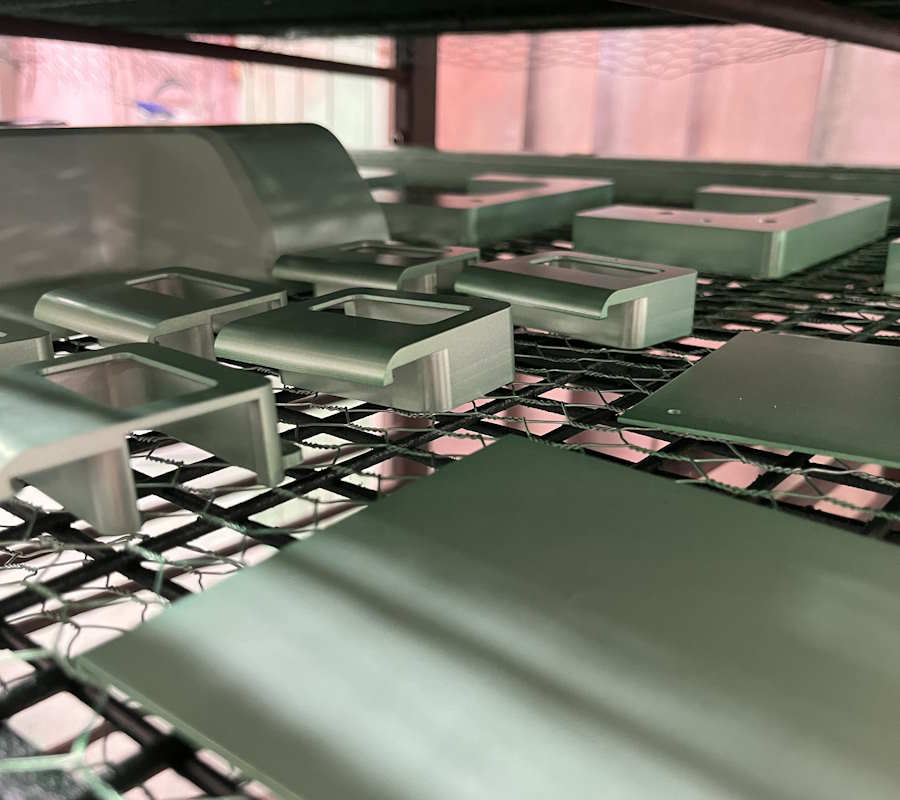

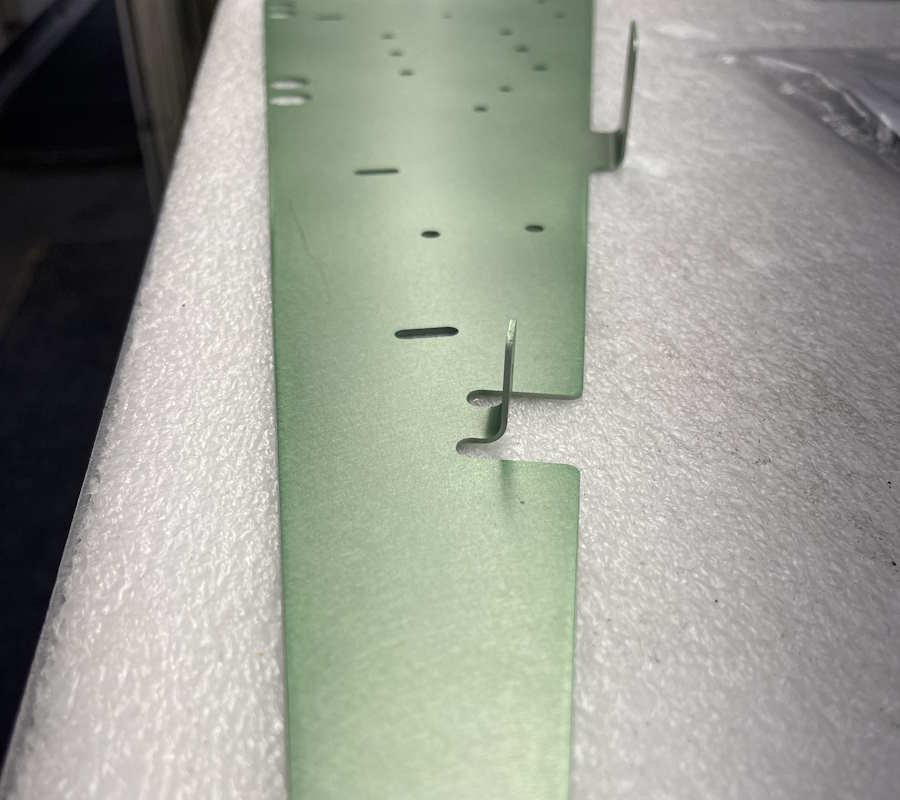

- Uniformity of deposit regardless of geometries